LEAK TESTING

- Condenser Negative Pressure Parts

- Tube-to- tube sheet leak in condensers/ Heat exchangers

- Lyophilizer /Freeze Dryer

- Vacuum Chambers/ tube Leak Test

- Leak testing Compressor train in Onshore/ offshore platform (90:10 He/Ne)

- Generator Leak Inspection

ALTERNATING CURRENT FIELD MEASUREMENTS (ACFM)

PULSED EDDY CURRENT TESTING (PEC)

PHASED ARRAY ULTRASOUND TESTING (PAUT)

TUBE INSPECTION

- Eddy Current Tube Inspection (ECT)

- Remote Field Eddy current Testing (RFET)

- Internal rotary inspection system (IRIS)

- Magnetic Flux Leakage (MFL)

CONVENTIONAL TESTING

- Ultrasonic Testing

- Positive Material Identification

- Visual Testing

MANPOWER SUPPLY SERVICE

- Tube Inspection Inspector

- IRATA Rope Access L1,L2 and L3 Inspecctor

- NDT Technician / L3 Inspector

- API Inspectors

SOLAR PANEL INSTALLATION

- ONLINE / OFF LINE GRID

OTHER SERVICES

BORESCOPIC / REMOTE VISUAL INSPECTION

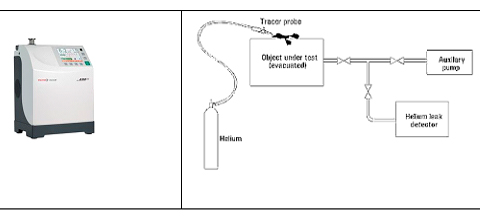

LEAK TESTING

Solar NDTT offers Helium Leak Testing based solutions of different types to meet our customer requirements.

Helium Mass spectrometer is an highly sensitive and reliable equipment to find out minute leaks/cracks in any system which is undergoing Leak testing.

We specialise in On-line Helium leak testing to find minute leaks on condenser using Helium gas in Power Plant, Vacuum Leak testing in Medical Equipments like Freeze Dryer/ Lyophilizer. Helium Leak Testing has the possibility to partly or fully automate the process, integrating it directly into the manufacturing line too if required.

In pipelines, we pressurize the equipment / pipeline with Nitrogen / Helium in the ratio of 90:10 to the testing pressure required by the client and check for leaks in all Joint areas. Even minute leaks can be identified using our Sensitive Equiment Helium mass spectrometer.

TUBE LEAK detection BY VACUUM TEST

Solar NDTT provides ultrasonic shear wave inspection for welds inspection as well as Ultrasonic Longitudinal Wave Inspection to perform tube leakage and corrosion scanning/mapping on the plant piping and pressure vessels as per the API 510 and API 570

Alternating Current Field Measurement (ACFM)

Alternating Current Field Measurement (ACFM) is a non-contact electromagnetic technique that detects and sizes defects in metals. It can be used to locate surface-breaking cracks in metals, such as in welds, and can provide information about the length and depth of the crack.

ACFM can work through thin coatings like paint, rust, or zinc-based coatings, surface preparation / cleaning is limited and is faster than other techniques. Accuracy is higher in this testing with no usage of chemicals.

Pulsed Eddy Current (PEC)

Pulsed Eddy Current (PEC) is an advanced electromagnetic inspection technology used in detecting flaws / wall loss and corrosion in ferrous materials such as carbon steel and cast iron. typically hidden under layers of coating, fireproofing, or insulation It provides a relative volumetric measurement converted into an averaged thickness measurement based on the calibration area. . There is no surface preparation needed including coating/insulation removal.

Benefits

Pulsed eddy current is one of the most versatile NDT techniques on the market. It can measure the remaining thickness of a component with a liftoff of any non-ferromagnetic form:

- Insulation with weather jacket (aluminum, stainless steel, galvanized steel)

- Concrete/Silicate

- Composite wrap/Polymer coating

- Marine growth

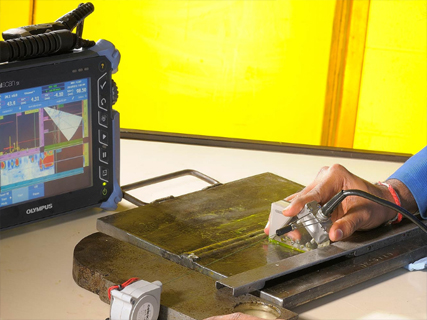

Phased Array Ultrasonic Testing (PAUT)

Phased Array Ultrasonic Testing (PAUT) is an advanced nondestructive examination technique that utilizes a set of ultrasonic testing (UT) probes made up of numerous small elements, each of which is pulsed individually with computer-calculated timing (“phasing”).

Phased array probes can be used manually in a free running mode scrubbing the surface of a component, attached to an encoder to record position, or mounted on a semi-automated or motorized scanner for optimum productivity. Phased array probes has the ability to quickly scan large areas for corrosion, cracking, and other defects with high resolution with suitable arrangements..

PAUT can be used to inspect almost any material where traditional UT methods have been utilized and is often used for weld inspections and crack detection.

PAUT systems can be used to inspect large surface areas quickly with high resolution, more quicker than Conventional UT, higher accuracy, repeatability, flexibility in scanning bends, elbows, safety than alternative RT tests.

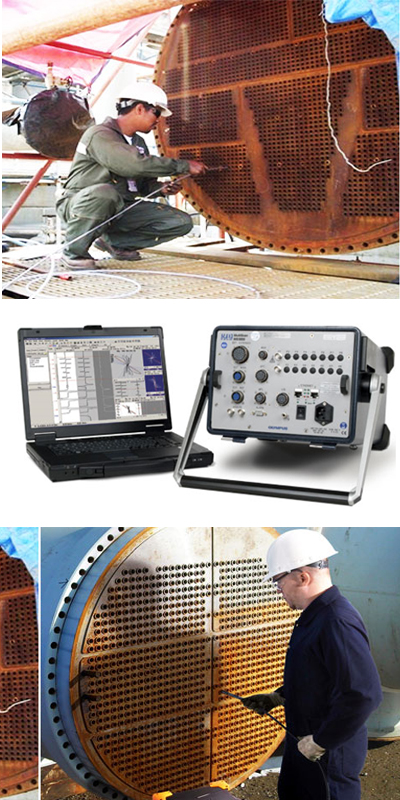

ECT/RFET/MFL/IRIS

Solar NDTT provides complete Condenser and Heat Exchanger tube inspection solutions for ferrous and non-ferrous tube materials using the following methods:

Eddy current testing is a well-established method of nondestructive testing that is used to examine nonferrous/nonmagnetic materials such as condenser and heat exchanger tubes in power generation plants. Eddy current testing reveals discontinuities in tubing, provides plant engineers with an accurate assessment of a unit’s condition, and is a tool for predicting the remaining useful life of the tubes.

- Internal Rotary Inspection Systems (IRIS)

IRIS is an ultrasonic based system for inspecting ferrous and nonferrous tubes from the inside. It is based on the Internal Rotating Inspection System (IRIS), which can be applied on almost any material. Accurate thickness measurements can be taken at any location along the tube, so small changes in thickness are measurable and the exact location of pitting and corrosion can be determined.

- Magnetic Flux Leakage Testing (MFLT)

Magnetic Flux Leakage Testing is used for ferromagnetic and Fin fan cooler tubes.

- Remote Field Eddy Current Testing (RFT)

Remote Field Eddy Current Testing is used for ferromagnetic tubes.

The basic RFT – Remote Field Testing probe consists of two coils (or multiple in pairs) in a send-receive configuration. Exciter coil is energized with a low frequency Alternating current to send a magnetic flux to the detector coil. The magnetic flux travels radially through the tube wall to the outside diameter, then propagates axially and then traverses back through the wall reaching to the detector coil.

PMI and UT

PMI Services

Solar NDTT provides Positive Material Identification (PMI) services to construction projects to identify or sort the different types of material. With PMI, the composition of materials in alloys can be accurately determined. It is particularly useful for high quality materials such as stainless steel and high alloy metals. While engineers push the boundaries of material capacity to the limit in their design, assurance that the proper material is used becomes of utmost importance.

UT Services

Solar NDTT provides ultrasonic shear wave inspection for welds inspection as well as Ultrasonic Longitudinal Wave Inspection to perform thickness measurement and corrosion scanning/mapping on the plant piping and pressure vessels as per the standards

BORESCOPE

SOLAR NDTT provides borescope inspections of heat exchangers pipelines, tanks, pressure vessels..Our borescope inspection technology can determine problems with welds, detect corrosion issues, identify blockages, examine for presence of cracks, as well as other discontinuities. Our technicians deliver accurate results, providing our clients thorough findings to problems that otherwise could lead to serious or potentially hazardous outcomes. In addition, our inspection solutions facilitate minimizing down time and potential financial losses for your company.

MANPOWER SUPPLY SERVICE

We can provide Manpower consultancy services by providing suitable Technicians/ Inspectors for Tube inspection/ IRATA Rope access job/ API Inspectors/ NDT TECHNICIAN/NDT LEVEL 3 as per the requirement of clients.

Man Power consultancy services

1.TUBE INSPECTION INSPECTOR

2. IRATA ROPE ACCESS L1, L2 AND L3 INSPECTOR

3. NDT TECHNICIAN/ L3 INSPECTOR

4. API INSPECTORS